What Wire Can Be Submerged in Water? Understanding Waterproof Connecting Cable Materials & Design

2025,05,07

When it comes to underwater or high-humidity environments, not all wires are built to last. For safe and long-term submersion, cable materials and construction methods must be carefully selected. At SUYI, we specialize in Waterproof Connecting Cable solutions that perform reliably in submerged conditions.

1.Best Material for Submersion: Polyethylene (PE)

Among all materials, Polyethylene (PE) and High-Density Polyethylene (HDPE) have proven to be the most durable for underwater use. They offer:

-Excellent water resistance

-Long-term seawater corrosion protection

-Strong insulation and mechanical stability

That’s why PE is the core material in many of our Waterproof Cable Assemblies, especially for sonar, lighting, and marine electronics.

2.How Waterproof Cables Are Constructed

-Water-blocking tapes or gel layers to prevent water migration

-Double-jacketed insulation for extra protection

-Tinned copper conductors for anti-corrosion performance

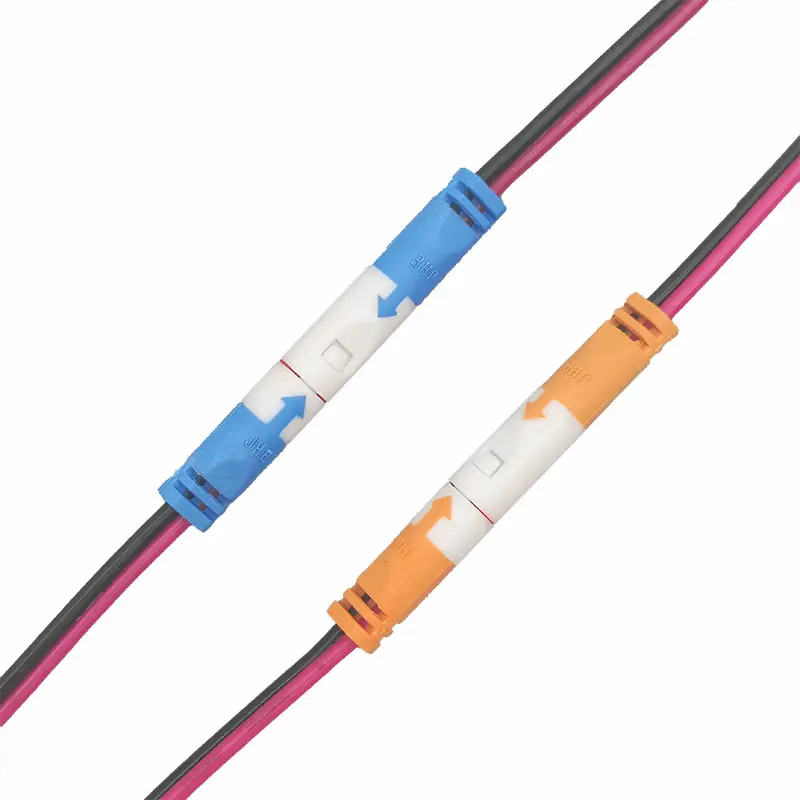

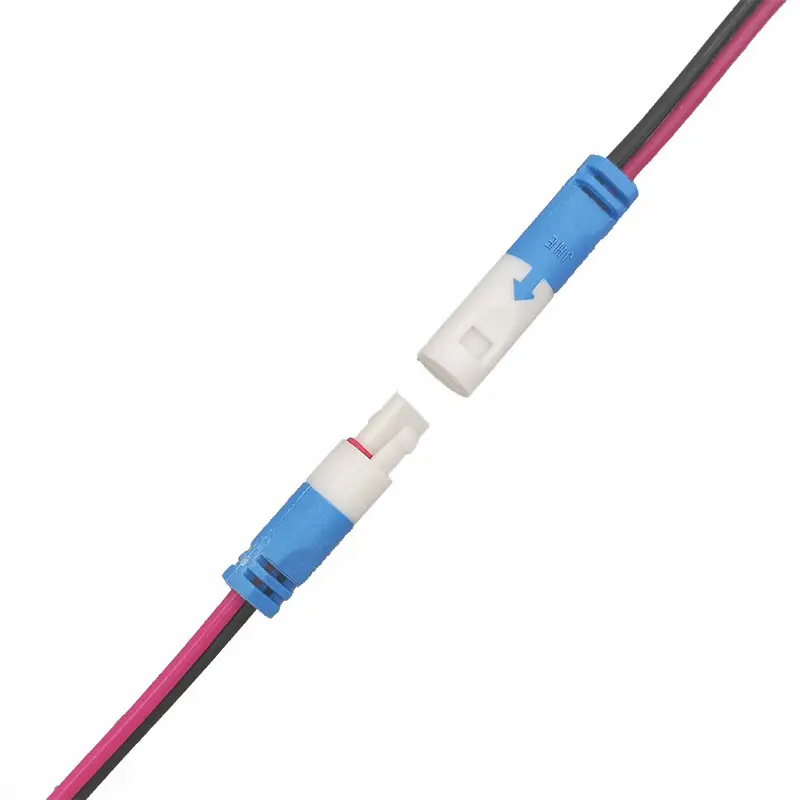

3.Recommended Waterproof Connector Types

SUYI provides various models to suit different submerged applications:

Each option is available in Plastic or Metal Waterproof Connector versions.

4.SUYI: Your Custom Waterproof Cable Partner

With over 10 years of manufacturing experience, Dongguan SUYI Electronics Co., Ltd. offers full customization:

-OEM/ODM support from drawing to delivery

-Custom overmolding, epoxy sealing, and multi-pin connectors

-Fast sampling and scalable production

Whether you need an M8

Waterproof Connector Cable or a rugged SW 24 Waterproof Connector Cable, SUYI delivers quality you can trust.